Semplastics’ X-FOAM™ is a new ceramic foam material capable of continuous use in air from cryogenic temperatures to above 1,300 °C, making it useful for many aerospace, furnace, construction, and heavy industrial use cases. Some variants are capable of use in air at even higher temperatures, and all variants will never catch fire even under continuous direct flame from a 2000 °C torch.

This rigid, machinable material has an incredibly low thermal conductivity of 0.034 W/m·K – only 1.5x more conductive than still air, approaching the insulating properties of many aerogel materials. But while X-Foam is 7 times lighter than water (only 0.15g/cc), it still has compressive strength in the hundreds of PSI.

How machinable is it? You can shape it in its final form using a hacksaw or a power drill or CNC machine, and it will hold a sharp edge. Pieces of X-Foam can be glued together with traditional high temperature cements or bonded together permanently as if one piece using Semplastics’ proprietary alumina glue.

Semplastics can also deposit a 60 µm layer of alumina on X-Foam to give it a pleasing, light gray finish that will not crack, delaminate, or powder off during thermal shock tests of 1,000 °C per second (see the video below). This coating is extremely durable and will survive thousands of temperature cycles in part because X-Foam exhibits no measurable outgassing, even in vacuum.

Finally, X-Foam has an exceptionally low heat capacity, and can be made with a waterproof skin made from the X-Foam material itself for use in outdoor environments.

X-Foam comes in a variety of shapes and sizes…reach out to us today!

Uncoated X-FOAM

Alumina Coated X-FOAM

X-FOAM Insulation and Thermal Shock Performance

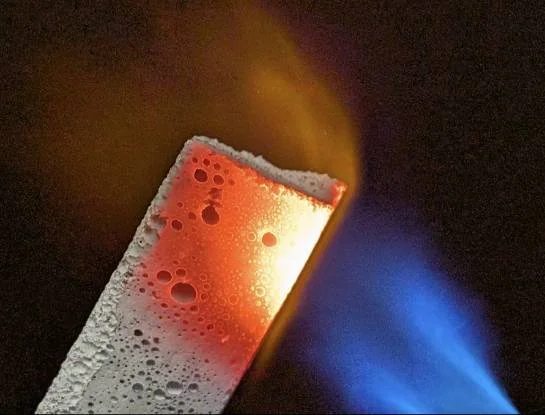

In this demonstration of X-Foam’s world-class thermal insulation ability (0.034W/m·K), a 1 centimeter thick piece of X-Foam protects water ice from the 1900°C propane flame.

In this demonstration, X-Foam is subjected to an extreme thermal shock—first submerged in liquid nitrogen at -196°C, then immediately exposed to an open flame from a propane torch. The test highlights X-Foam’s exceptional thermal resilience, structural stability, and resistance to cracking under rapid and severe temperature changes.

This test highlights the performance of X-Foam enhanced with a proprietary diffusion barrier coating. The coated foam is rapidly cycled from submersion in liquid nitrogen to direct flame exposure, showcasing its ability to withstand extreme thermal gradients without visible damage, delamination or structural compromise.

X-FOAM in the News

We were recently highlighted in a news segment showcasing how X-FOAM™ is redefining high-performance, heat-resistant materials. Watch the video to learn how our technology is helping solve real-world industrial challenges.

Applications

Aerospace Insulation

Molten Metal Filtering

Hot Gas Permeability

Furnace Insulation

Pyrolysis Insulation

Oven Furniture

About

X-FOAM

-

Semplastics X-FOAM and X-FOAM HT give designers new options in the realms of:

Low mass foam core CMCs for 1400ºC and 1600ºC applications

Oxidation resistant back-up insulation for coated Carbon/Carbon

Low thermal mass insulation for ovens, furnaces, and kilns

Very high temperature and high-permeability gas filtration and re-usable bio-filters

-

There are two ways to control the shape and size of this material.

It can be designed in the green state and fired with custom curves and shapes.

It is very easily machines in its final shape using basic tools and holds an edge.

Customizable Pores Per Inch